Built-in Test Equipment (BITE) is a vital add-on in many Air Traffic Control systems avoiding fatal errors and reducing system down-times. However, the efficiency of BITE and hence passenger safety depends on the personnel's familiarization with the equipment, rapid recovery strategies and the choice of the right equipment. This article introduces into BITE and suggests related qualification aids for ATCO and ATSEP.

Let us start with a definition of BITE.

Definition: Built-in-Test-Equipment (BITE) is a set of on-board hardware of software-based diagnosis aids helping to locate faults or wrong calibration. BITE may include signaling of errors, self-checking circuits and correction circuits [1].

Let us now dive deeper into the conception of BITE.

Usage of BITE

BITE is conceived for in-fields maintenance by ATSEP, to indicate system status and to indicate whether a system has been assembled properly.

Centralized vs. Decentralized

The general BITE architecture depends on the nature and scale of the monitored technical system. Sometimes it makes sense to use several decentralized BITE units, incorporated into replaceable elements (e.g., circuit boards), to test their functionality. Such solutions are by design very close to and optimized on the monitored systems. When the system is replaced, the BITE is replaced as well. The disadvantage is that error indication is by default not central. It may be missed by the personnel.

A centralized BITE requires a dedicated hardware which is connected to the operational systems. An illustrative example are RASS-S systems, designed to continuously monitor the calibration and correct operations of primary and secondary radars.

A centralized BITE requires a dedicated hardware which is connected to the operational systems. An illustrative example are RASS-S systems, designed to continuously monitor the calibration and correct operations of primary and secondary radars.

More generic and not exclusively ATC related are the so-called SCADA systems.

These Surveillance, Control and Data Acquisition solutions are connected to a multitude of systems and aggregate system data including emergency warning to a central location.

Today, more and more components with on-board BITE have status APIs, which can be connected to centralized SCADA systems.

This combines the advantages of the

- decentralized concept (closer to the hardware / software, potentially including self-repair) with the

- centralized concept (aggregated analytics and emergency warnings at a central control center or dashboard).

Interruptive vs. Continuous

In the interruptive concept (I-BIT), normal system operation is suspended during the time of the test. This may be necessary e.g., when testing NavAids systems or radars under various circumstances (e.g. switching off antenna segments) which might endanger safety and security of aviation. Also this is a typical approach during a system's power up process.

Other solutions, in particular those which conduct preventive monitoring like the RASS-S system operate continuously without disturbing the system's normal operation.

Hardware vs. Software

Some BITE solutions are purely software based and do not require additional hardware. For example the power-up BITE solution of SkyRadar's PSR and FMCW provides a software based testing procedure that compares actual measurement results with stored data. Other solutions like the RASS-S require additional hardware and software to conduct the monitoring.

BITE: Advantages and Disadvantages

The benefits are multiple. We can list

- shorter and fewer system down-times

- reduced fault finding time

- reduced life cycle costs [1]

- increased system security and safety of passengers, personnel and concerned civilians (e.g., those living under the trajectory of an aircraft)

These points are convincing, given that an additional solution can increase efficiency and safety and save operating costs in the same time.

However, BITE also has its downsides.

Disadvantages

Due to actual capabilities and limitations BITE may cause irritations and disturbances through so-called spurious error signals. This may cause unjustified down-times, operational delays or replacement of non-erratic components.

Also, the right user qualification as well as BITE-strategies are required to deploy BITE correctly and effectively in an ATC context. Such qualification concerns the operators (ATCO) as well as the technical service and maintenance personnel (ATSEP).

Qualification and Training Equipment

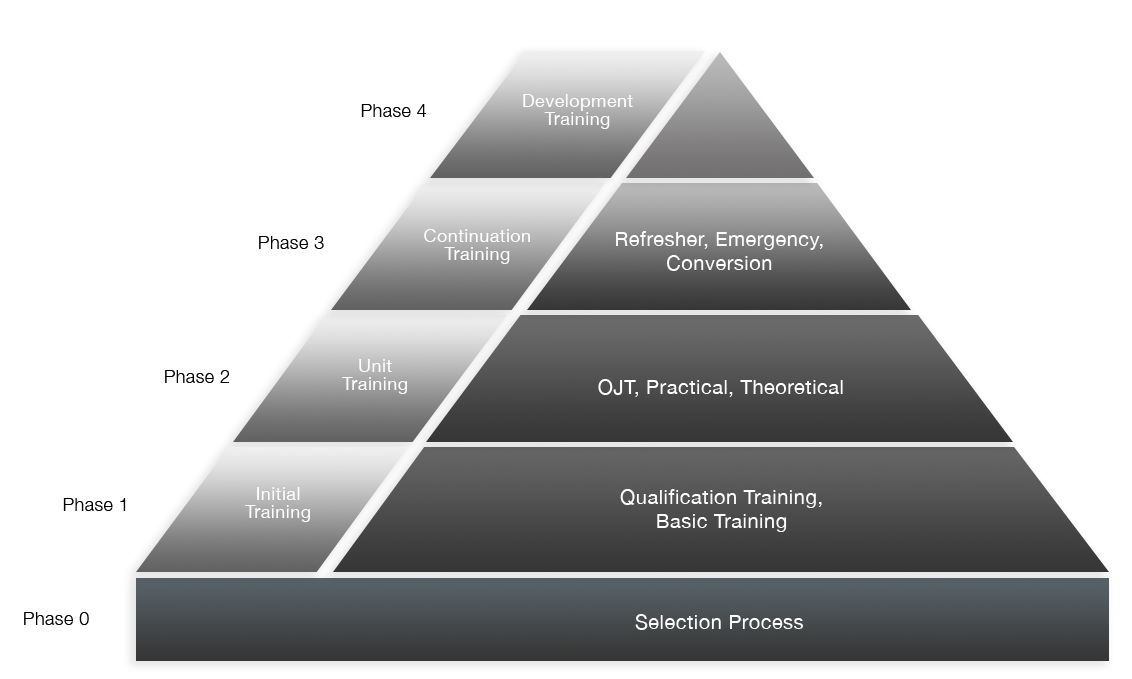

ICAO's training pyramid for ATSEP and for ATCO defines the 3 (ATCO) / 4 (ATSEP) Phases of qualification. BITE systems can be introduced in Phase 1 of the training, but they will have their focus in the phases 2 and 3.

BITE strategies should be escalation strategies that provide instructions based on different levels of escalation

- Level 1: Compliant (cooperative)

- Level 2: Resistant (passive)

- Level 3: Resistant (active)

- Level 4: Assaultive (bodily harm)

- Level 5: Assaultive (lethal force)

The core training equipment (Aerodrome simulators, bigger radar set ups and simulators) should include BITE, either as integrated part or as add-on. Thus, the handling of BITE and BITE-related escalation strategies can be trained.

SkyRadar and BITE

SkyRadar includes BITE in several training modules.

RASS-S Training

The interplay of a pedagogically enhanced RASS-S and SkyRadar's modular pulse radar provide the perfect training environment for centralized, continuous BITE scenarios.

The modular pulse radar represents the primary radar tower. The RASS-S system provides continuous monitoring and diagnosis. Trainers and Trainee can experiment on it, change configuration and develop their individual BITE-based escalation routines.

PSR and FMCW base module

The two base modules PSR and FMCW include software based interruptive BITE scenarios, where correct data is compared to actual data in the phase of the initial start up. In addition, various status logs are available continuously in a system status screen.

Multi-Modal Radar

Other than the powerful RASS-S system, the multi-modal radar can be complemented with central BITE components. Those range from simple watchdogs to complex SCADA systems. Modern IoT solutions allow for easy and standardized approches. However, to be compliant with ICAO Unit Training or Continuation training, the system architecture should replicate the real system architecture as much as possible.

Aerodrome Simulators

Our Tower, APP and ACC simulators are actually real operational systems, complemented with simulators on the signal input side (and replacing the pilots by pseudo-pilots). The whole system has various functional surveillance systems implemented. Like with the Multi-modal radar, continuous system monitoring can be added and customized similarly to the existing operational system.

The aerodrome simulator, the multi-modal radar and the RASS-S system can be implemented as a whole centralized and continuous BITE solution. SkyRadar is the only supplier world-wide able to supply such an end-to-end ATSEP based training solution (which serves in the same time as full ATCO training system for ATC processes.

Exceeding ATSEP and ATCO: the AVSEC and logistics training solutions

The CARGO training system for Aviation Security and Logistics training includes an enhanced WIN CC based SCADA system.

Also the fire fighting system includes a SCADA based BITE system.

Conclusion

Built-in Test Equipment offers a multitude of opportunities to optimize ATC and to turn air traffic safer and more efficient. However, it requires the right strategies, equipment, training plans and training equipment.

References

- [1] Evaluation of Built-In Test (2001), by M. Pecht, M.Dube, M. Natishan, R. Williams, J. Banner and I. Knowles. in: IEEE Transactions on Aerospace and Electronics Systems, 37 (1)

- Systems Engineering in Military Projects (2010), by Timothy Cathcart, Kim Fowler, David Tyler. In: Mission-Critical and Safety-Critical Systems Handbook, Design and Development for Embedded Applications, p.p. 461-570